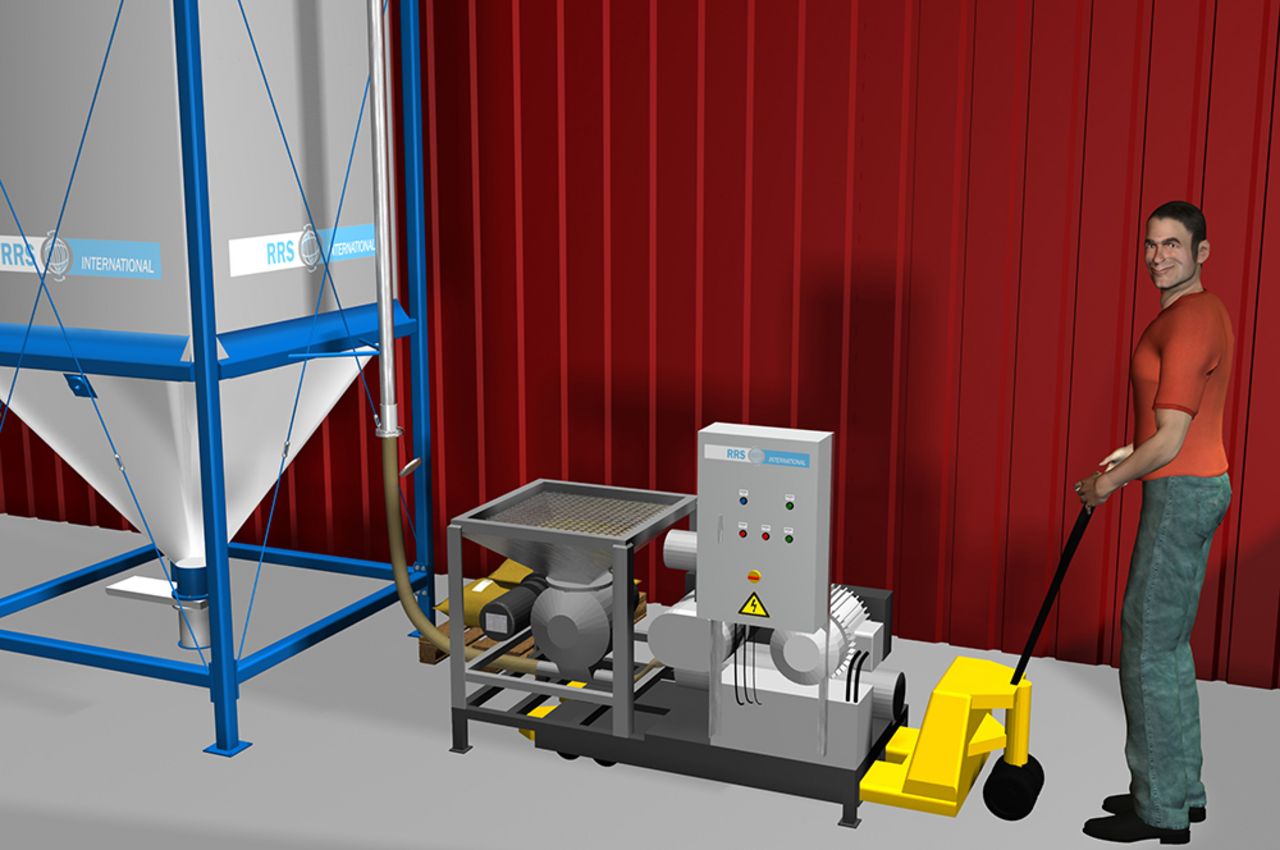

Pressure conveying stations

The pressure conveying station is used for the manual emptying of plastic pellets from 25 kg bags and for the filling of silos by pneumatic pressure conveying. The bags are slit by an operator and lifted onto the feeding container. The pellets fall into the container and the rotary feeder below it. The rotary feeder doses the granulate carefully into the conveyor pipe. From there the granulate is blown with overpressure through the conveyor pipe into the silo.

Mobile pressure conveying station

- Steel rack

- De-bagging container made of stainless steel

- rotary valve

- Air blower with pressure control valve

- Control cabinet

- Conveyor pipe, length 5m

| Item number | Conveying capacity (to/h) |

|---|---|

| DFST-04-01 | 4,0 |

| DFST-06-01 | 6,0 |

These specifications are based on the assumption that the plastic granulate has a bulk weight of 0,6 to/m³ – if the bulk weight is lower, also the conveying capacity in tons will be lower.